With over a decade of experience in Anchoring technology and extensive research in developing new fastening systems for various applications, Elantor Solutions has always been offering you safe & economical solutions.

In our strive for providing our customers with complete end to end solutions, we are proud to launch our Anchor Bolt (Threaded Bars) & Re-Bar fixing chemical – Mr. Mortar 390 (Formerly known as Mr Bond)

Features of Mr. Mortar

Hilti HITRE 500 OR FCHE FIS EM 390

|

|

|

High tensile & compressive strength |

Very low shrinkage contributing to maximum dimensional stability |

Fast Cure, user-friendly & Fast Cure, user-friendly &Cost efficient |

|

Applications of Mr. Mortar

- Connection/ Renovation / upgrades of secondary post-installed rebars

- Anchoring light structural steel connections such as steel columns, beams

- Anchoring secondary steel elements

- For light and medium-duty applications such as window bars, sanitary equipment, awnings, air conditioning systems, lights

Base Materials Mr. Mortar works on

Strong, reliable and easily installed fastenings in concrete and masonry materials

Strong, reliable and easily installed fastenings in concrete and masonry materials

Mr. Mortar works with

Why choose Mr. Mortar Pure Epoxy Resin over others?

Pure Epoxy Resin |

Mr. Mortar, being a Pure Epoxy Resin provides high performance and forms a strong adhesive bond.

Because of its pasty nature, mortar allows greater flexibility during installation. Because of the long working hours, rectifications can be made easily. |

One solution to all needs |

The USP of Mr. Mortar is that it is a one-stop solution to any base material and any substrate. You don’t have to look out for a different mortar whether you are looking for grouting or anchoring.

Mr. Mortar works on concrete, rock, ALC or hollow material along with chemical anchor bolts, threaded rods and reinforcing bars. |

Most Competitive Price |

Mr. Mortar is one of the most affordable products in terms of price for the quality it provides. In simple words, value for money lies at the heart of this product. |

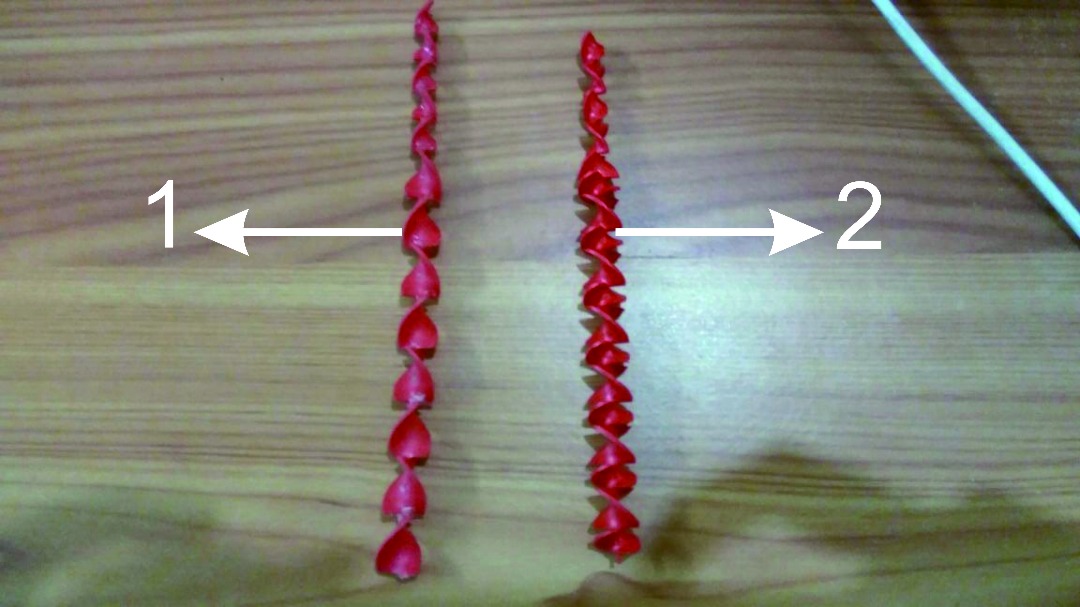

Most efficient Mixer Nozzle |

The static nozzle we provide allows for best mixing of both the components. The numbers of mixing cycles per stroke in our mixing nozzle are far more than our counterparts.

Notice the slits in our Nozzle (2) and that of others (i.e. 1). |

No more manual mixing |

Proper dispensing equipment allows the user to get benefits of 2 adhesives without weighing & mixing them manually. |

QR Code |

Scanning the QR Code on the cartridge gives you the practical and exact idea on the ml consumption of mortar required for Bolts & Re-bars of different sizes and lengths.

|

We also provide Premium services like Anchor Bolt or Re-Bar Pull-Out Tests (Both destructive and non-destructive) on site, Applicator Service for our Anchors, Re-Bars and Mr. Mortar and customized packaging.

Know more about our Premium services right here – https://elantorsolutions.com/anchor-pull-out-tests-applicator-services/

Pull Out Test on site

On special request, we also provide Anchor Bolt or Re-Bar Pull-Out Tests on site.

This helps you determine the resistance of the base material during the Design Phase as well as evaluate the quality and safety of our Chemical, thus ensuring compliance with local guidelines after installation.

Our trained applicators carry out destructive pull-out proof load test on regularly calibrated test equipment to ensure reliable results.

This test is conducted in the presence of the customer on site, post which he is provided with the Pull Out Evaluation Report containing all the technical details and help –

- Check the quality, safety and tensile strength of post-installed rebar and fastening systems after installation. This also helps establish the failure load of anchor or verification of supporting the resistance of Anchorage.

- Ensure the load resistance and quality of your design are OK.

- Determine resistance values of base materials not commonly used.

We recently conducted a Pull Out Test on a client’s site. Here is the report – PULL OUT TEST REPORT – ACE GAS CONVERSIONS PVT. LTD.

We go out of our way to make sure you are fully convinced before you make your first purchase with us.

CHECK OUT THE ENTIRE PHOTO GALLERY HERE Hilti HIT RE 500

Testing Certificate for Threaded Bolts and Re-bars

All necessary tests have been carried out in a well-renowned laboratory on various parameters and met all the criteria laid down successfully.

Global Lab has NABL accreditation in Mechanical / Chemical / NDT & Calibration discipline. Global Lab is one of the selected laboratories to provide more than 200 tests & more than 25 calibrations under NABL accreditation.

Threaded bar M12 Pull Out Test Certificate

Threaded bar M20 Pull Out Testing Certificate

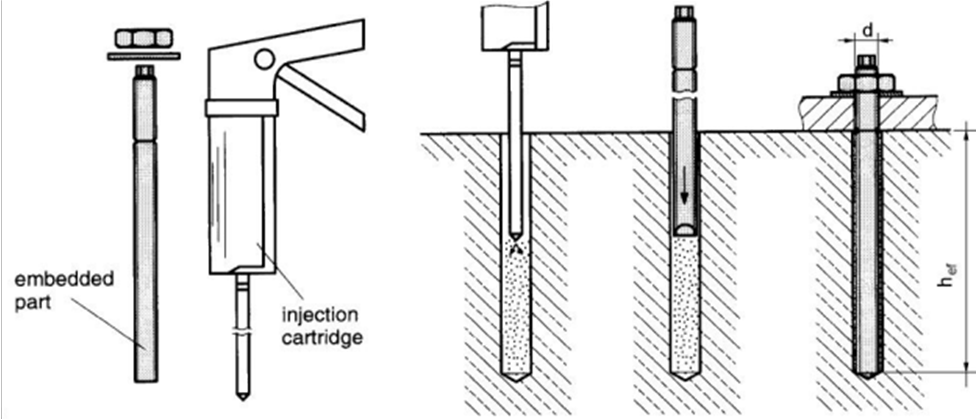

The procedure of using Mr. Mortar

Anchor Bolt/ Rebar fixing Pure Epoxy Resin based chemical

Mr. Mortar is an Injection cartridge system consisting of two resin components in separate compartments mixed proportionately in the nozzle when triggered using the dual caulking gun.

Just like Pure Epoxy RESIN BASED Hilti HIT RE 500 OR FISCHER FIS EM 390 S

user to get benefits of 2 adhesives without weighing & mixing

them manually.

If all this got you charged up, take the next step. Call us. Ask for our catalogue. Fix an appointment. Or, simply drop in an email. At Elantor Solutions, any response of yours is valuable.

No expansion forces

No expansion forces Strong vibration resistant properties

Strong vibration resistant properties